A well-functioning and resilient infrastructure is the foundation of every successful

community. To meet future challenges, industries and their infrastructure must be ugraded.

Access to good infrastructural facilities supports businesses, supports industrial growth,

promotes innovation and enhances productivity.

Being manufacturers of safety and critical component, technology development has been a

focus area in ROBUST. Rigorous testing, continuous upgradation of in-house technology and

support from strategic development partners has enabled ROBUST to enhance technical

competencies at all levels.

Robust creates tailored solutions for all its customer’s braking and friction demands around

the world using cutting-edge manufacturing facilities equipped with the latest automated

technologies and computerized machinery.

-

CNC TURNING MACHINE: A computer numerically controlled machine or CNC machine is a form of machine, a material removal process, which is used to create rotational parts by cutting away unwanted material. In CNC turning the unfinished roller is fixed on an axis and rotated while the turning equipment is brought closer to the rotating Metal Roller in order to create the Anchor Pin and Cam Rollers.

-

PNEUMATIC POWERPRESS: A pneumatic press derives its primary mechanical action such as shearing, punching, bending, forging, drawing, extruding, assembly or other actions from a pressure source by the means of compressed air. In This Automatic Powerpress all the Web and Tables are Stamped on a 400T capacity Press.

PNEUMATIC POWERPRESS: A pneumatic press derives its primary mechanical action such as shearing, punching, bending, forging, drawing, extruding, assembly or other actions from a pressure source by the means of compressed air. In This Automatic Powerpress all the Web and Tables are Stamped on a 400T capacity Press. -

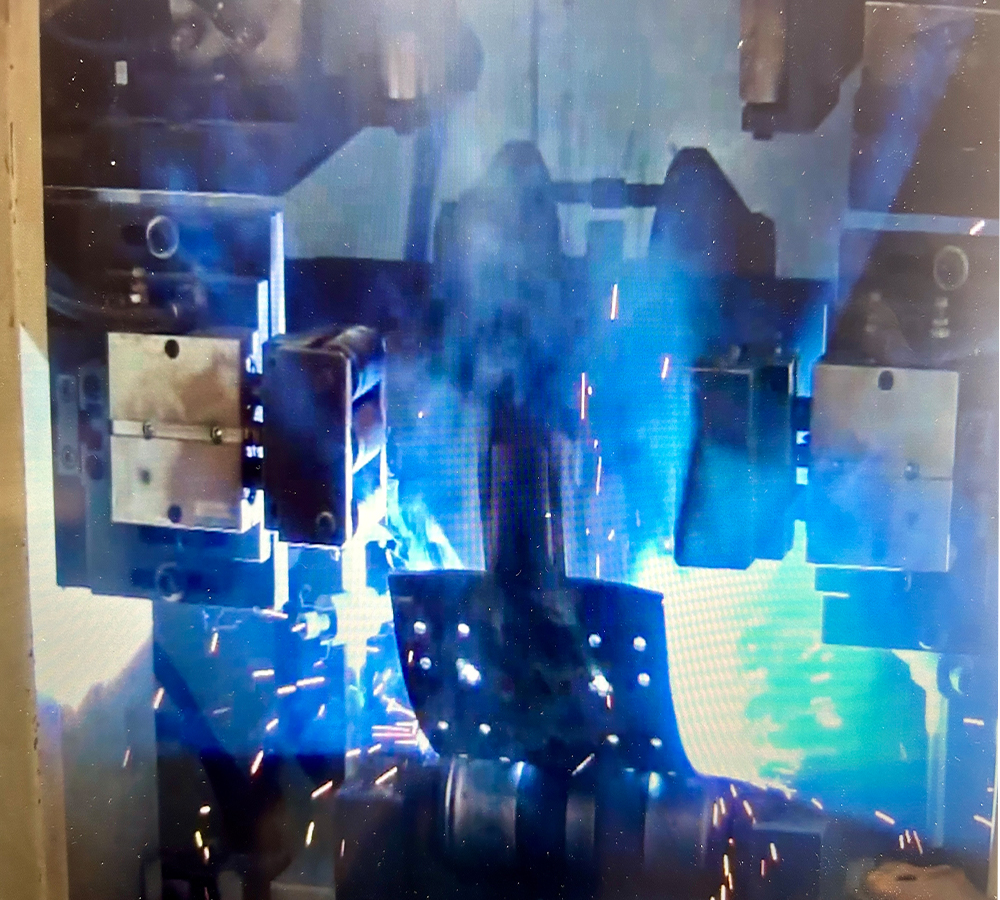

SPM FOR BRAKE SHOE WELDING: The special purpose projection welding machine is specially designed for welding brake shoe assemblies. The machine is equipped with basic welding transformer, microprocessor based control, pneumatically actuated vertical welding head and special rotatory indexing fixture with drives etc.

-

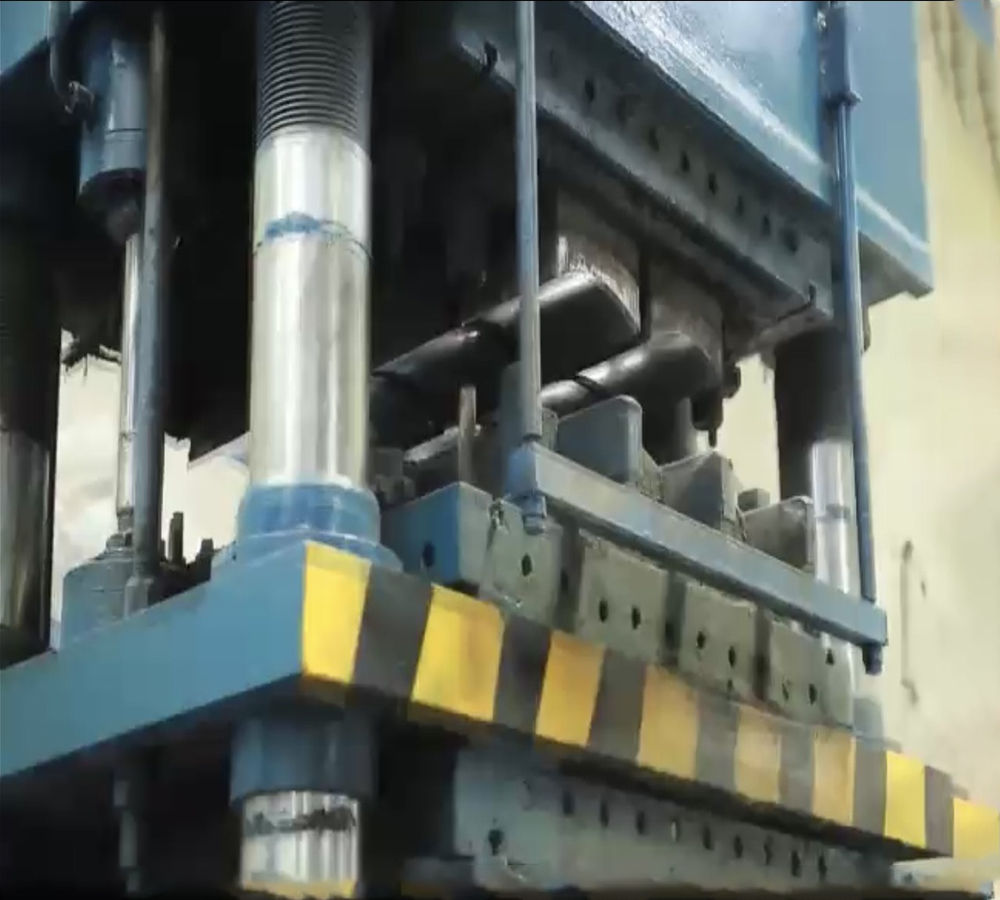

HYDRAULIC PRESS: A hydraulic press is a machine using a hydraulic cylinder to generate comprehensive force. Hydraulic presses are used in molding Brake Linings and Brake Pads, Coining the Brake Shoe to match the diameter.

HYDRAULIC PRESS: A hydraulic press is a machine using a hydraulic cylinder to generate comprehensive force. Hydraulic presses are used in molding Brake Linings and Brake Pads, Coining the Brake Shoe to match the diameter. -

AUTOMATIC GRINDER: The special purpose projection welding machine is specially designed for welding brake shoe assemblies. The machine is equipped with basic welding transformer, microprocessor based control, pneumatically actuated vertical welding head and special rotatory indexing fixture with drives etc.

-

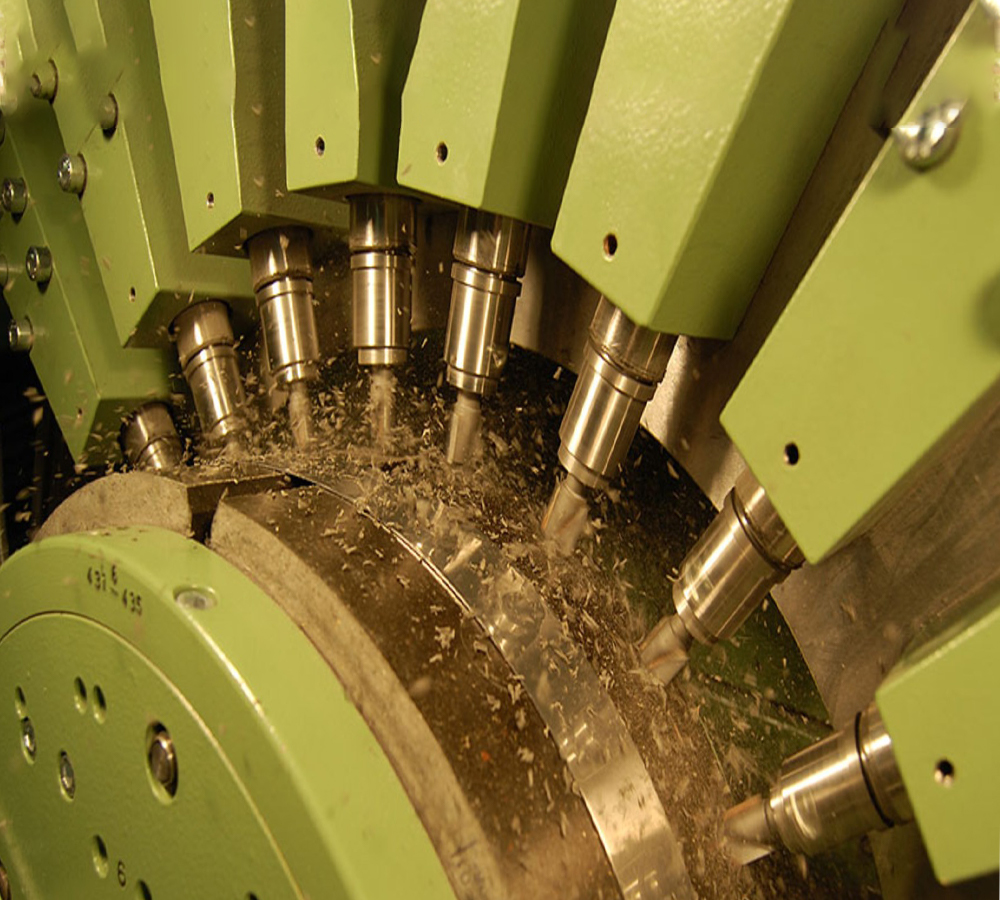

MULTI DRILLING MACHINE: A machine that drills several holes in Brake Lining simultaneously and reproduces the same pattern of holes in several identical pieces in mass production work. The feeding motion is obtained by raising the work table.

MULTI DRILLING MACHINE: A machine that drills several holes in Brake Lining simultaneously and reproduces the same pattern of holes in several identical pieces in mass production work. The feeding motion is obtained by raising the work table. -

INDUCTION HARDENING MACHINE: An induction hardening machine is a type of equipment used in industrial settings for the surface hardening of metal parts. It utilizes the principle of electromagnetic induction to heat up specific areas of a metal component quickly and efficiently. We Surface harden all our Brake Shoe ends and all our Anchor Pins / Cam Rollers for Case hardening.

-

AUTOMATIC RIVETING MACHINE: An automatic riveting machine for heavy-duty truck brake shoes is a specialized piece of equipment used in the manufacturing process of brake systems for trucks and other heavy vehicles. The primary purpose of the automatic riveting machine is to efficiently and accurately assemble brake shoes by riveting them together. Automatic riveting machines play a critical role in the efficient and precise production of heavy-duty truck brake systems, contributing to the safety and reliability of commercial vehicles on the road.

AUTOMATIC RIVETING MACHINE: An automatic riveting machine for heavy-duty truck brake shoes is a specialized piece of equipment used in the manufacturing process of brake systems for trucks and other heavy vehicles. The primary purpose of the automatic riveting machine is to efficiently and accurately assemble brake shoes by riveting them together. Automatic riveting machines play a critical role in the efficient and precise production of heavy-duty truck brake systems, contributing to the safety and reliability of commercial vehicles on the road.